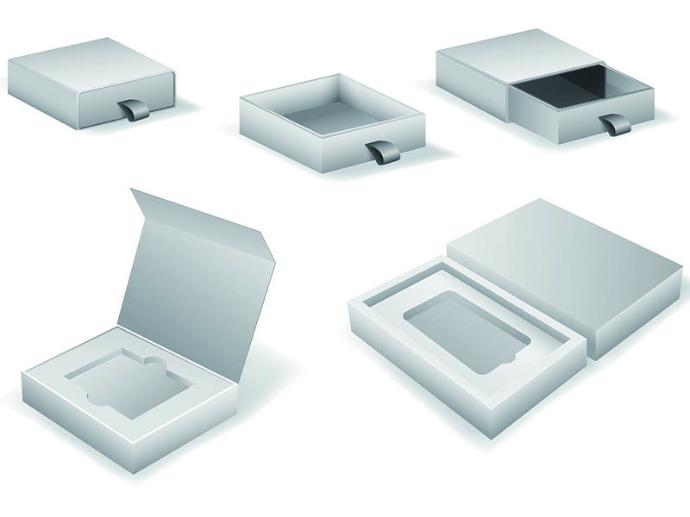

Luxury Black Matte Rigid Folding Magnet Wine Paper Box

Send us your project details

(scroll down to get more info)

MOQ(Minimum Quantity): Starting from 500 boxes for standard shapes.

Material: Clay-coated news back(CCNB), clay-coated white back(CCWB), solid bleached soleplate (C1S), both-side art board(C2S), grey board, kraft board, kraft paper, wood pulp paper, art paper, textured paper, metallic paper, gold foil paper, silver foil paper, etc.

Printing: CMYK, PMS, Digital printing, offset printing, screen printing. UV printing, gravure printing, electrostatic printing and so on.

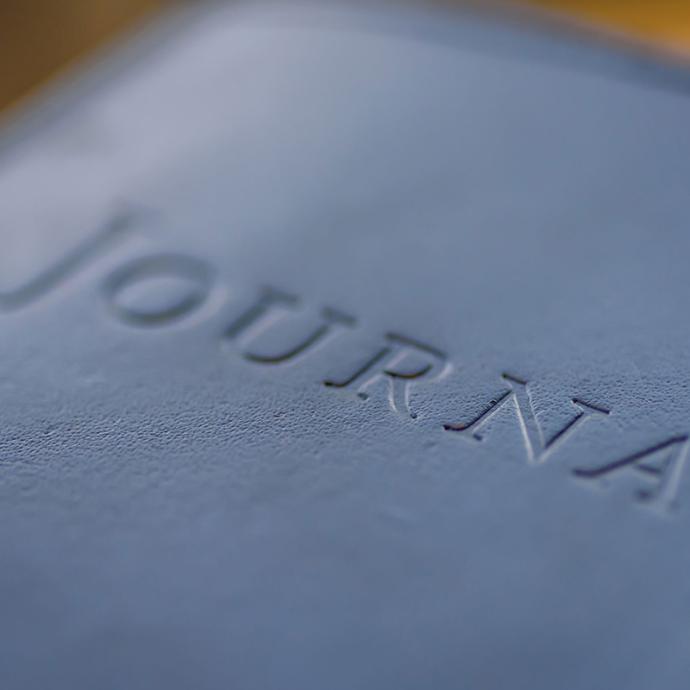

Finishing: Aqueous coating, varnishing, calendering, UV-coating, sport UV-coating, matt lamination, gloss lamination, embossing, debossing,

gold hot stamping, cold hot stamping, emboss + stamp, pattern embossing, etc.

After Printing: Die-cutting, gluing, stapling, laminating.

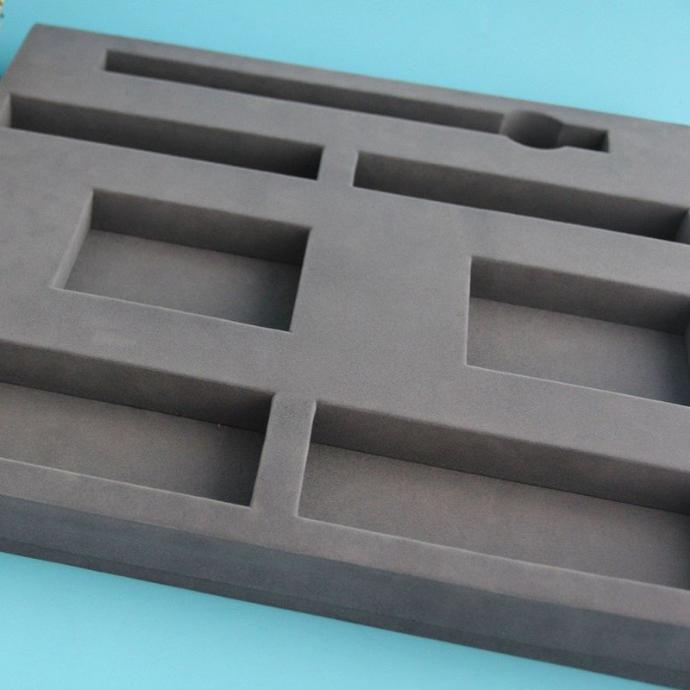

Inserts: Foam inserts, paper inserts, cardboard inserts, EVA inserts, silk, velvet lining, PVC blister, PETG blister.

Accessories: Magnetic locks, metal locks, ribbon & bows, plastic handles, leather handles, macrame handles, and child-resistant locks.

Turn Around Time/Lead Time: 15-35 business days, depending on different paper box types.

Proof: Flat view, 3d mock-up, physical sampling (on Request).

Shipping Time: 5-7 working days for air shipment, 25-35 business days for sea shipment.

Payment Terms: 30% deposit at order, 70% before shipping.

Payment Methods: T/T.

Custom Samples: 5-7 business days.

How a paper gift box is made with KETSANA PACK

A simple process guide of the paper rigid box manufacturing, the process may vary according to the types & complexity of the gift boxes.

Paper Selection

The general gift box wrapping paper is made of double copper and matte copper paper, the commonly used grammage: 128g, 105g, 157g, 128g, 105g, 157g. And grey-board.

File & Plate Making

In order to print properly, the correct file is the first step and an essential process to check in detail. Plate making is converting the graphic information in the computer into a medium that can be used for printing.

Printing & Color Proofing

Gift boxes are outer packaging boxes; the box's content is what consumers see the most and represent the brand image. Thus, a fully color-proofing check is a must to ensure printing quality.

Finishing

Most packaging boxes have a layer of film on the surface to protect the printing and enhance the visual aesthetic. This surface treatment process is called finishing, including but not limited to glossy varnish, UV coating, spot UV coating, matt/glossy lamination, embossing/debossing, etc.

Die-cutting / V slotting

Die-cutting is an extremely important part of the process, especially for gift packaging boxes to be shaped as desired; the technical requirements for die-cutting are even higher, and the precision and accuracy determine the quality of the product. The gray board that is attached to the printing paper usually needs to be V-shaped to be able to form the box.

Laminating /Gluing

Lamination is a necessary process in the gift box process. It generally refers to gluing a piece of paper to another part of the paper. For example, in the case of perfume boxes, it is done by gluing the printed patterned paper to the top of a shaped gray board. This beautifies the appearance of the box body and improves the added value of the paper box.

Assembling & Inspection

Usually, The gift boxes are packed with other accessories such as inserts, manuals, and other parts to complete the product. After putting all the components into the box, we ensure the box's perfect appearance by cleaning the possible prints on the rigid boxes. A full round inspection will also be applied before the final packing.

Final Packing

Pack every gift box into well-calculated cartons for space-saving and high protection purposes. We suggest the best way and quantity pack for each carton box to help customers save on shipping costs.

Paper Materials

Duplex Grey Chipboard

Single Side Coated Board

Gold Foil Paper

Silver Foil Paper

Holographic Paper

Metallic Paper

Textured Paper

Nature Kraft Paper

Printing Methods

Offset Printing

Digital Printing

UV Printing

Screen Printing

Inks

Water-based Ink

Eco-friendly Soy-based Ink

Fluorescent Ink

Oil-based Ink

Finishing

Gloss Lamination

Matt Lamination

Soft-touch Finishing

Spot UV Coating

Embossing

Debossing

Gold Hot Stamping

Silver Hot Stamping

Add-on Accessories

EVA & Foam Inserts

Ribbon & Bows

Metal & Magnetic Locks

Various Handles

Select A Type or Request A Customized One

Browse through our extensive catalog of custom boxes and packaging, and pick the perfect type, material, printing options, finishing effects, additional options, and quantity.

To find out more, simply fill out and submit the request a quotation form, including their specifics, and our sales representatives will contact you within 1 - 2 business days.

Consultation & Quotation

Our team will engage with your unique needs to better understand your project and will prepare a quote for you. Based on those needs, our specialists can provide expert recommendations regarding your request. When the read-made artworks are ready, send them to us, and you will obtain your personalized quote within 1 to 2 business days.

Proof of The Artworks

Your specifications will be professionally incorporated after you confirm the quotation. The structural and artwork dimensions are designed and sent to you for final confirmation before the order is sent to production.

Sampling and Prototyping

We advise an initial prototyping and sampling process for all orders to confirm that all specifications are met before moving forward with the mass production order. At this point, any adjustments can be made based on your preliminary prototype sample to perfect your mass production order to your taste.

Production & Follow-ups

Once the order is put into production, you will for sure get up to date weekly report for each step of your order; we also organize conference calls before the completion of the production when the face-to-face visit is not available.

Inspection & Logistics

Our QC team examines the product quality at every production line to ensure the smoothness of the manufacturing. Once your order is ready for assembling, another full round inspection will be taken place and we will provide a detailed inspection report before shipping. You can choose your own logistic companies or let us take care of it for you. We are able to help you with the international shipping networks we build.

Looking for specific printing and finishing options?

No problem! Just let us know your preferences, we will help you define the right process.